Supercar Engine Technology – LaFerrari vs. Aventador

Environmental concerns continue to dictate the ever increasing efficiency of traditional combustion engines and have even led to the use of hybrid powertrains in exotic cars. What will follow is a brief comparison of how Ferrari and Lamborghini have managed to keep their V12 powerplants relevant — it’s all about efficiency.

Ferrari HY-KERS

Ferrari chose to employ a hybrid powertrain, “HY-KERS” (hybrid kinetic energy recovery system), in their most recent hypercar, which uses technology derived directly from Formula 1 — a sport that in recent years has see vast improvements in the efficiency of its turbocharged, hybrid engines. LaFerrari produces about half the CO2 emissions of Ferrari Enzo, while still offering the most powerful engine in a Ferrari road car, ever, with 963 total horsepower.

Ferrari chose to employ a hybrid powertrain, “HY-KERS” (hybrid kinetic energy recovery system), in their most recent hypercar, which uses technology derived directly from Formula 1 — a sport that in recent years has see vast improvements in the efficiency of its turbocharged, hybrid engines. LaFerrari produces about half the CO2 emissions of Ferrari Enzo, while still offering the most powerful engine in a Ferrari road car, ever, with 963 total horsepower.

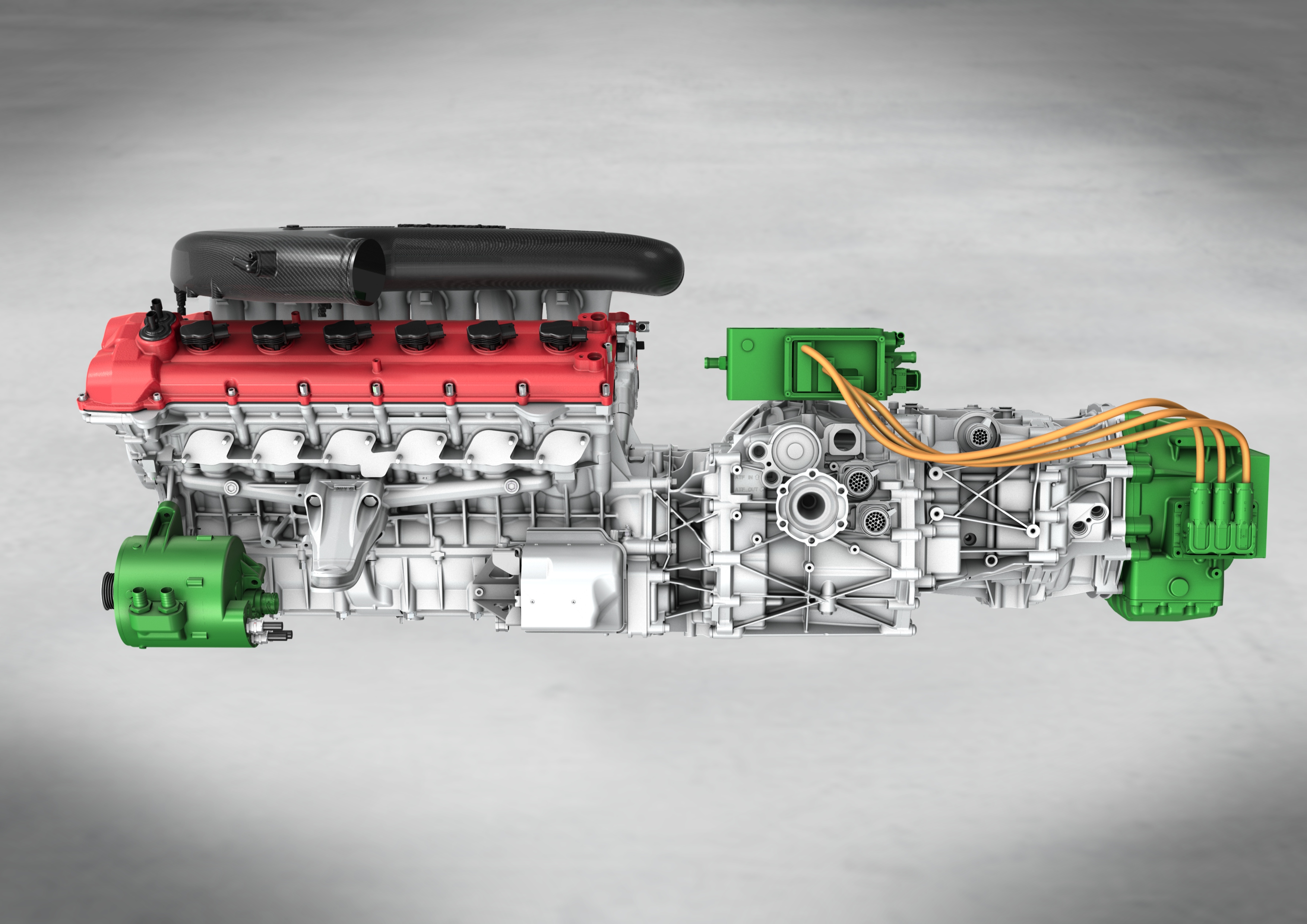

The HY-KERS powertrain combines a traditional V12 combustion engine with an electric hybrid drive system. Supplied by Magneti Marelli, the hybrid drive system is comprised of two electric motors (EM1 and EM2), a double inverter, and a battery control system, which itself consists of a BSM (Battery Management System) and 8 BMCs (Battery Module Controllers).

The “Hy-Power,” or EM1 electric motor will be most familiar to Formula 1 fans, and can be identified in diagrams as the green highlighted unit attached directly to the transmission. It recovers kinetic energy under braking, which is then converted into electricity and stored in the batteries — a block of 120 cells assembled at Ferrari’s Formula 1 facilities alongside the KERS systems for their Formula 1 racing cars. This extra energy can then be used to accelerate the vehicle, generating an additional 163hp on top of the combustion engine’s peak of 800hp.

EM2 is an auxiliary electric motor which gets its power from the combustion engine. It maintains the charge level of the KERS lithium ion batteries — which are mounted to the floor of the chassis for weight distribution purposes — and after its electric current is changed from a high to low voltage (12V) by one of the double inverters, it can also power the vehicle’s accessories such as its lights.

Lamborghini Aventador V12 “L539”

When Lamborghini debuted their latest flagship V12 model in 2011, Aventador, they decided they would keep the powertrain naturally-aspirated, in line with their brand’s philosophy and image.

Their trademark V12 engines have stood the test of time, harking back in one way or another to the 3.5-liter V12 used in the 350 GT over 50 years ago.

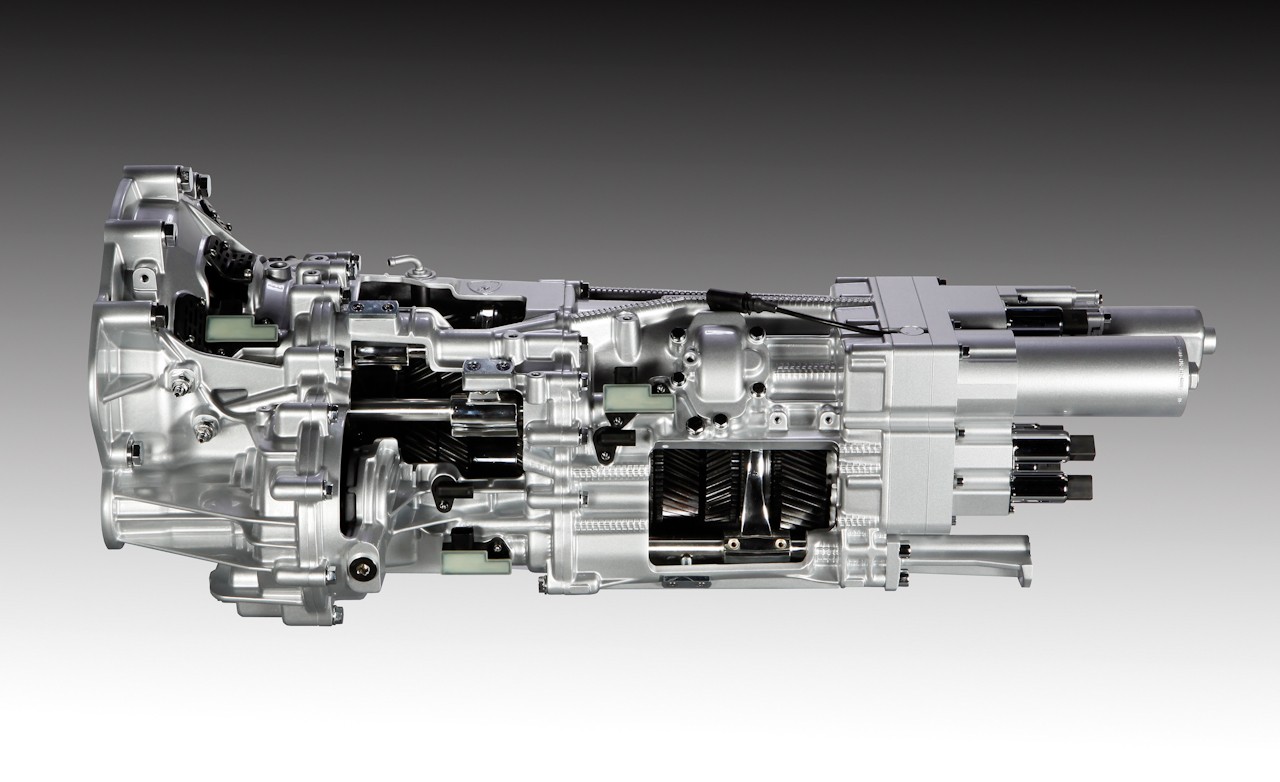

Lamborghini invested in an all-new V12 engine for Aventador, codenamed “L539,” to replace the outgoing Murciélago’s “L537” V12, which made 632hp at 8000rpm and 487lb-ft at 6000rpm. L539, which produces 691hp at 8250rpm and 509lb-ft at 5500rpm, is lighter, sits lower, and consumes less fuel than its predecessor, while still delivering an 8% increase in power and about 20% less CO2 emissions.

Aventador’s V12 engine uses an open-deck design, meaning the cylinder walls are not directly in contact with the outer edges of the block. This is meant to improve cooling and reduce weight and is preferable for high-revving, naturally-aspirated engines.

The block itself is made of an aluminum-silicon alloy, as are the cylinder heads. There are two heads, one for each cylinder bank, and they weigh just 46lb. each. Adding silicon to aluminum creates an alloy that is harder, expands less, and absorbs more heat than pure aluminum – favored over steel in certain applications due to its light weight and low cost.

Lamborghini continue to evolve their legacy V12 engine in clever ways, but when Aventador is replaced in five or six years from now, will they still be able to avoid the use of turbochargers/hybrid power?